Powering Bitcoin Mining with Oil Well Energy

Bitcoin's thirst for energy is no joke. Annually, it gulps down 77.78 TWh—yep, that's about what entire countries like Chile, Kazakhstan, or Belgium use. And with that comes a hefty carbon footprint: 36.95 million tons of CO2, putting it on par with New Zealand's total emissions.

The crypto mining world has been aware of this environmental footprint from the get-go, constantly looking for ways to dial it back. According to some eye-opening research from the University of Cambridge's Center for Alternative Finance, a whopping 76% of miners are now using renewable energy—think solar, wind, and water. It's a clear nod towards greener mining practices.

What's really cutting-edge, though, is how some mining outfits are getting creative with energy sources. They're looking beyond the usual suspects to things like geothermal energy and, get this, electricity generated from associated petroleum gas (APG)—you might know it as Flare Gas. It's a byproduct of drilling for oil that's usually either pumped back down to keep the pressure up or sent off to gas processing plants. But now, there's a game-changing move to use this gas to power up Bitcoin mining operations right there at the oil fields.

Digging into Oil Field Bitcoin Mining

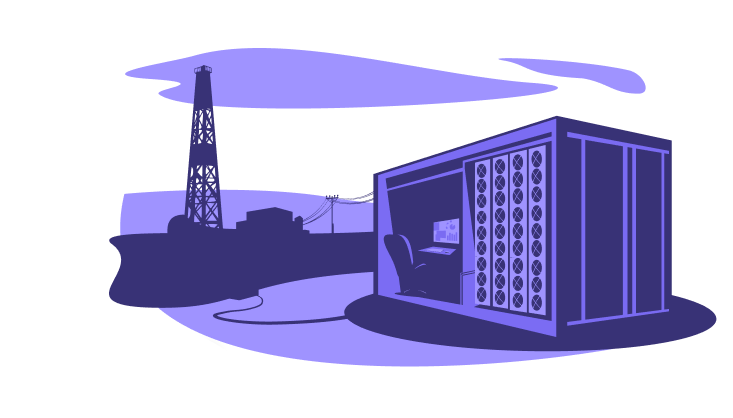

Let's take a closer look at how Bitcoin mining setups at oil fields are making a difference. By rolling out mobile mining rigs packed with the latest computing tech, these pioneers are capturing and converting APG into electricity. This isn't just making good use of what would otherwise be a wasted resource; it's providing a much-needed power source for the demanding task of mining Bitcoin.

Stay tuned as we explore the mutual benefits of this unique partnership between the old world of oil extraction and the cutting-edge realm of Bitcoin mining.

The Journey of Gas from Oil: What's It All About?

Ever wonder where the gas that powers so much of our world comes from? Oil, the planet's most coveted natural resource, plays a massive part. Back in 2019, countries around the globe traded a whopping 292 billion tons of oil, raking in about $3.35 trillion, as per the United Nations.

This oil doesn't just fuel our cars, planes, and ships; it's also a key ingredient in making everything from roads (asphalt) to everyday items like plastics, synthetic fabrics, and even the petroleum jelly in your medicine cabinet. Plus, it's where we get benzene, a building block for common meds like aspirin and paracetamol.

But here's where it gets technical: the oil we use, known as “commercial” oil, meets some pretty strict standards, like those in the ISO 3735:1999. Basically, this stuff has to be pretty pure, with no more than 1% water and other impurities.

So, how do we get this clean, commercial oil? It comes from something called formation fluid, a mix of oil, water, dissolved gas, and tiny rock bits that oil companies draw up from deep underground.

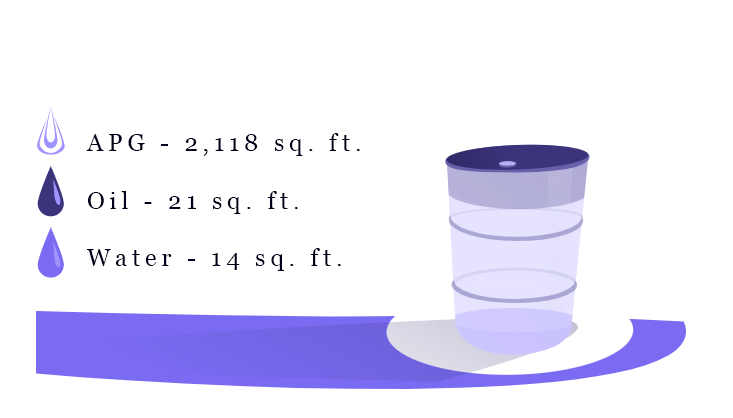

Once this fluid hits the surface, the associated petroleum gas (APG) in it really expands, up to hundreds of times its original volume. For a clearer picture, imagine this: from every cubic meter of that underground mix, you end up with about 0.58 cubic meters of oil, 0.35 cubic meters of water, a little bit of impurities (0.07 cubic meters), and a whopping 62 cubic meters of APG.

That's a lot of gas coming up with the oil, and it's a key part of what makes the whole oil extraction process so fascinating—and important.

Typically, when extracting a cubic meter of formation fluid from a field, the result is:

Bitcoin's thirst for energy is no joke. Annually, it gulps down 77.78 TWh—yep, that's about what entire countries like Chile, Kazakhstan, or Belgium use. And with that comes a hefty carbon footprint: 36.95 million tons of CO2, putting it on par with New Zealand's total emissions.

The crypto mining world has been aware of this environmental footprint from the get-go, constantly looking for ways to dial it back. According to some eye-opening research from the University of Cambridge's Center for Alternative Finance, a whopping 76% of miners are now using renewable energy—think solar, wind, and water. It's a clear nod towards greener mining practices.

What's really cutting-edge, though, is how some mining outfits are getting creative with energy sources. They're looking beyond the usual suspects to things like geothermal energy and, get this, electricity generated from associated petroleum gas (APG)—you might know it as Flare Gas. It's a byproduct of drilling for oil that's usually either pumped back down to keep the pressure up or sent off to gas processing plants. But now, there's a game-changing move to use this gas to power up Bitcoin mining operations right there at the oil fields.

Digging into Oil Field Bitcoin Mining

Let's take a closer look at how Bitcoin mining setups at oil fields are making a difference. By rolling out mobile mining rigs packed with the latest computing tech, these pioneers are capturing and converting APG into electricity. This isn't just making good use of what would otherwise be a wasted resource; it's providing a much-needed power source for the demanding task of mining Bitcoin.

Stay tuned as we explore the mutual benefits of this unique partnership between the old world of oil extraction and the cutting-edge realm of Bitcoin mining.

The Journey of Gas from Oil: What's It All About?

Ever wonder where the gas that powers so much of our world comes from? Oil, the planet's most coveted natural resource, plays a massive part. Back in 2019, countries around the globe traded a whopping 292 billion tons of oil, raking in about $3.35 trillion, as per the United Nations.

This oil doesn't just fuel our cars, planes, and ships; it's also a key ingredient in making everything from roads (asphalt) to everyday items like plastics, synthetic fabrics, and even the petroleum jelly in your medicine cabinet. Plus, it's where we get benzene, a building block for common meds like aspirin and paracetamol.

But here's where it gets technical: the oil we use, known as “commercial” oil, meets some pretty strict standards, like those in the ISO 3735:1999. Basically, this stuff has to be pretty pure, with no more than 1% water and other impurities.

So, how do we get this clean, commercial oil? It comes from something called formation fluid, a mix of oil, water, dissolved gas, and tiny rock bits that oil companies draw up from deep underground.

Once this fluid hits the surface, the associated petroleum gas (APG) in it really expands, up to hundreds of times its original volume. For a clearer picture, imagine this: from every cubic meter of that underground mix, you end up with about 0.58 cubic meters of oil, 0.35 cubic meters of water, a little bit of impurities (0.07 cubic meters), and a whopping 62 cubic meters of APG.

That's a lot of gas coming up with the oil, and it's a key part of what makes the whole oil extraction process so fascinating—and important.

Typically, when extracting a cubic meter of formation fluid from a field, the result is:

To get oil ready for the market, it goes through a bit of a clean-up process. First off, they separate the mix coming out of the ground—oil, associated gas, and water—right in the separation units. After that, the oil gets an extra scrub before it's sent down the pipeline for shipping.

The water that's pulled out during this process isn't wasted; it's actually pumped back into the well to keep the pressure up. And the associated gas? That's either put to work in special power plants or used in other ways.

Now, let's talk about Associated Petroleum Gas (APG). This stuff is a cocktail of hydrocarbons, from C1 to C10, mixed with carbon dioxide, oxygen, nitrogen, and a bit of water vapor.

Methane, which you might know as CH4, is the star of the natural gas show. APG's got a lot of the same stuff, but it's a bit trickier to handle because of all the extra bits and pieces in it.

Methane can make up to 82% of APG, and releasing it straight into the atmosphere is a big no-no. Why? Well, methane's a supercharged greenhouse gas—84 times punchier than carbon dioxide, according to the climate change experts at the United Nations IPCC.

So, what do oil folks do with APG after they've separated it from the crude? They've got to deal with it pronto. One way is turning it into dry gas. It's all about keeping things safe and minimizing the environmental footprint.

They do it like this:

Processing into dry gas

The water that's pulled out during this process isn't wasted; it's actually pumped back into the well to keep the pressure up. And the associated gas? That's either put to work in special power plants or used in other ways.

Now, let's talk about Associated Petroleum Gas (APG). This stuff is a cocktail of hydrocarbons, from C1 to C10, mixed with carbon dioxide, oxygen, nitrogen, and a bit of water vapor.

Methane, which you might know as CH4, is the star of the natural gas show. APG's got a lot of the same stuff, but it's a bit trickier to handle because of all the extra bits and pieces in it.

Methane can make up to 82% of APG, and releasing it straight into the atmosphere is a big no-no. Why? Well, methane's a supercharged greenhouse gas—84 times punchier than carbon dioxide, according to the climate change experts at the United Nations IPCC.

So, what do oil folks do with APG after they've separated it from the crude? They've got to deal with it pronto. One way is turning it into dry gas. It's all about keeping things safe and minimizing the environmental footprint.

They do it like this:

Processing into dry gas

APG gets shipped off to processing facilities to get cleaned up—removing the hydrogen sulfide, the heavy stuff, and any water vapor. These plants turn it into something pretty similar to natural gas, known as dry stripped gas. However, this whole process doesn't really pay off for the more out-of-the-way fields, where getting the gas out and about just isn't worth the cost.

Gas injection

Gas injection

APG is pumped back into the reservoir to help squeeze out more oil. This approach needs a bunch of fancy gear: equipment to treat the gas, compressors to push it down, wells specifically for injecting the APG, and tanks to store it all. It's a pretty intricate setup.

Electricity generation

Electricity generation

They use APG to generate electricity right there on site to power the field's operations. However, the electricity produced from this associated gas might not always cover all the energy needs of the oil field.

Flaring

Flaring

Flare Gas gets burned off in flares, sending soot, carbon dioxide, and as much as 4.5% methane up into the atmosphere. Both carbon dioxide and methane are big players in the greenhouse effect, contributing to global warming.

Countries around the world are cracking down on this practice by hitting companies with fines for flaring APG. Thanks to these measures, there's been a drop in how much APG is flared, though the numbers are still pretty high.

Back in 2018, the biggest names in oil were responsible for flaring a staggering 145 billion cubic meters of APG—that's about what all the countries in Africa use in natural gas over a year. And the kicker? The value of all that wasted gas? A cool $16 billion.

Countries around the world are cracking down on this practice by hitting companies with fines for flaring APG. Thanks to these measures, there's been a drop in how much APG is flared, though the numbers are still pretty high.

Back in 2018, the biggest names in oil were responsible for flaring a staggering 145 billion cubic meters of APG—that's about what all the countries in Africa use in natural gas over a year. And the kicker? The value of all that wasted gas? A cool $16 billion.

Mining with Associated Gas: The Lowdown

Back in 2015, the World Bank kicked off a plan aiming for zero gas flaring by 2030, and now, oil producers from 32 countries are on board. Big oil's making strides, too. Take Norway's Equinor, for instance, which now effectively uses up to 95% of its associated gas. But there's a hitch—getting rid of APG burning entirely isn't quite possible yet.

One big challenge is that many new oil fields just don't have the setup to process and move associated gas, and there aren't enough facilities around to handle it all.

But here's a cool twist: oil operations can convert APG into electricity, which opens up some interesting doors. That electricity can power up all sorts of things, including cryptocurrency mining operations. So, instead of wasting this gas, it's being turned into a valuable resource for the digital age.

Back in 2015, the World Bank kicked off a plan aiming for zero gas flaring by 2030, and now, oil producers from 32 countries are on board. Big oil's making strides, too. Take Norway's Equinor, for instance, which now effectively uses up to 95% of its associated gas. But there's a hitch—getting rid of APG burning entirely isn't quite possible yet.

One big challenge is that many new oil fields just don't have the setup to process and move associated gas, and there aren't enough facilities around to handle it all.

But here's a cool twist: oil operations can convert APG into electricity, which opens up some interesting doors. That electricity can power up all sorts of things, including cryptocurrency mining operations. So, instead of wasting this gas, it's being turned into a valuable resource for the digital age.

Turning associated gas into electricity is a win-win situation. Oil companies get to sell the power, and miners get to use up that gas instead of letting it go to waste. Plus, miners score because they're getting their electricity at great rates, and it's a greener option, too, since gas-fired power plants have a smaller environmental footprint compared to coal-fired ones.

Take this as an example: a single 1MW container can fit 350 Antminer S19 devices. This setup would use about 200–250 thousand cubic meters of APG each month. But the cool part? That amount of power could net miners up to 8 BTC a month. Not too shabby, right?

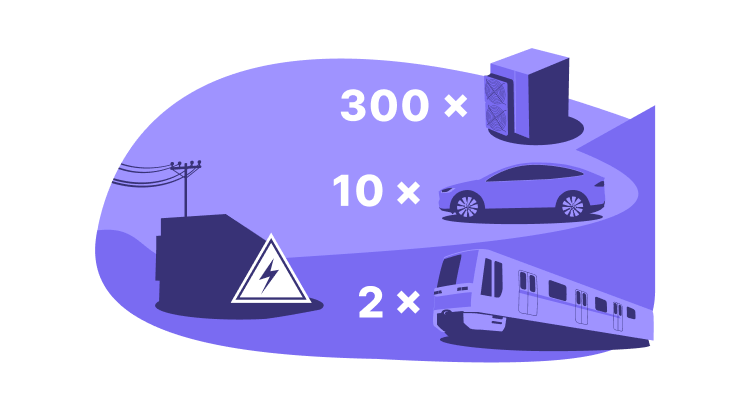

A mobile mining container with a capacity of up to 1 MWh is enough for:

Take this as an example: a single 1MW container can fit 350 Antminer S19 devices. This setup would use about 200–250 thousand cubic meters of APG each month. But the cool part? That amount of power could net miners up to 8 BTC a month. Not too shabby, right?

A mobile mining container with a capacity of up to 1 MWh is enough for:

· Running 300 Antminers S19 Pro ASIC miners, churning out 0.2 BTC daily;

· Charging up 10 Tesla Model X vehicles all at once;

· Juicing up the engines for a pair of subway cars leading the way.

Mining with APG in the U.S.: A Historical Snapshot

Back in '72, the UN's first environmental conference in Stockholm laid down 26 principles for a healthier planet, urging smarter use of resources and cutting back on harmful emissions. This led oil producers to start cutting down on APG flaring, and by 1990, countries like Norway, Canada, and 33 U.S. states had put restrictions or outright bans on the practice. Fast forward from 1996 to 2018, and the World Bank notes a 37% drop in APG flaring.

Sometimes, turning APG into market-ready gas doesn't add up financially, especially for remote fields. It might make more sense for these companies to cop the fines for flaring than to ship the gas miles away.

But here's a silver lining: using APG for mining. It's a clever fix for the transport dilemma since the mining operations use the electricity right where it's produced. Enter AiPROENERGY, a Texas-based trailblazer, mastering this approach across North America with air and immersion mining containers, setting up and maintaining mining gear, and fully managing mining operations. At AiPRO we are betting big on reducing CO2 emissions through this method. Contact us via email: info@aiproenergy.com for further details.

Wrapping Up

Oil companies are constantly on the hunt for smarter, more beneficial ways to use APG. By hooking up computing power directly to oil field generators for data centers—they can make a positive impact. This strategy allows oil producers to efficiently dispose of APG while offering tech and mining firms cost-effective electricity. It's a forward-thinking approach that benefits everyone involved, from the oil fields to the final digital output.

· Charging up 10 Tesla Model X vehicles all at once;

· Juicing up the engines for a pair of subway cars leading the way.

Mining with APG in the U.S.: A Historical Snapshot

Back in '72, the UN's first environmental conference in Stockholm laid down 26 principles for a healthier planet, urging smarter use of resources and cutting back on harmful emissions. This led oil producers to start cutting down on APG flaring, and by 1990, countries like Norway, Canada, and 33 U.S. states had put restrictions or outright bans on the practice. Fast forward from 1996 to 2018, and the World Bank notes a 37% drop in APG flaring.

Sometimes, turning APG into market-ready gas doesn't add up financially, especially for remote fields. It might make more sense for these companies to cop the fines for flaring than to ship the gas miles away.

But here's a silver lining: using APG for mining. It's a clever fix for the transport dilemma since the mining operations use the electricity right where it's produced. Enter AiPROENERGY, a Texas-based trailblazer, mastering this approach across North America with air and immersion mining containers, setting up and maintaining mining gear, and fully managing mining operations. At AiPRO we are betting big on reducing CO2 emissions through this method. Contact us via email: info@aiproenergy.com for further details.

Wrapping Up

Oil companies are constantly on the hunt for smarter, more beneficial ways to use APG. By hooking up computing power directly to oil field generators for data centers—they can make a positive impact. This strategy allows oil producers to efficiently dispose of APG while offering tech and mining firms cost-effective electricity. It's a forward-thinking approach that benefits everyone involved, from the oil fields to the final digital output.