Mining farms are notably energy-intensive systems. Both miners and their cooling systems consume significant amounts of energy. It is estimated that globally, mining farms and data centers account for about 3% of the world's total electricity consumption, a figure expected to rise. Moreover, as high-performance processors evolve, the heat generated by miners increases. Currently, data center cooling systems can account for 30–50% of total energy consumption.

There's a growing belief that traditional air-cooling systems will eventually struggle with heat dissipation, as air will remove heat from components more slowly than these elements generate it. Without addressing cooling challenges, increased temperatures could lead to reduced efficiency and systematic failures.

Cost-saving considerations also play a significant role - in some instances, adopting alternative cooling solutions can drastically reduce capital and operational expenses. This drives miners' interest in alternative equipment cooling methods, like immersion cooling.

What Is Immersion Cooling?

Immersion cooling involves submerging the entire miner in a thermally conductive dielectric liquid, effectively removing heat without compromising the electronics' functionality due to the liquid's non-conductive properties.

CPU water blocks are gaining popularity for high-performance systems where air's heat capacity is insufficient. However, a liquid cooling system doesn't necessarily require water blocks, pipes, and pumps. Immersion cooling offers a less traditional approach. It's a form of liquid cooling without the need for a sealed refrigerant circuit, making the entire miner cooling process more straightforward and effective.

There's a growing belief that traditional air-cooling systems will eventually struggle with heat dissipation, as air will remove heat from components more slowly than these elements generate it. Without addressing cooling challenges, increased temperatures could lead to reduced efficiency and systematic failures.

Cost-saving considerations also play a significant role - in some instances, adopting alternative cooling solutions can drastically reduce capital and operational expenses. This drives miners' interest in alternative equipment cooling methods, like immersion cooling.

What Is Immersion Cooling?

Immersion cooling involves submerging the entire miner in a thermally conductive dielectric liquid, effectively removing heat without compromising the electronics' functionality due to the liquid's non-conductive properties.

CPU water blocks are gaining popularity for high-performance systems where air's heat capacity is insufficient. However, a liquid cooling system doesn't necessarily require water blocks, pipes, and pumps. Immersion cooling offers a less traditional approach. It's a form of liquid cooling without the need for a sealed refrigerant circuit, making the entire miner cooling process more straightforward and effective.

Historically, immersion cooling wasn't pioneered for miners. Cooling transformers by immersing them in oil tanks dates back to the 19th century, a practice that remains common today with transformer oils classified as a type of mineral oil.

In Detail

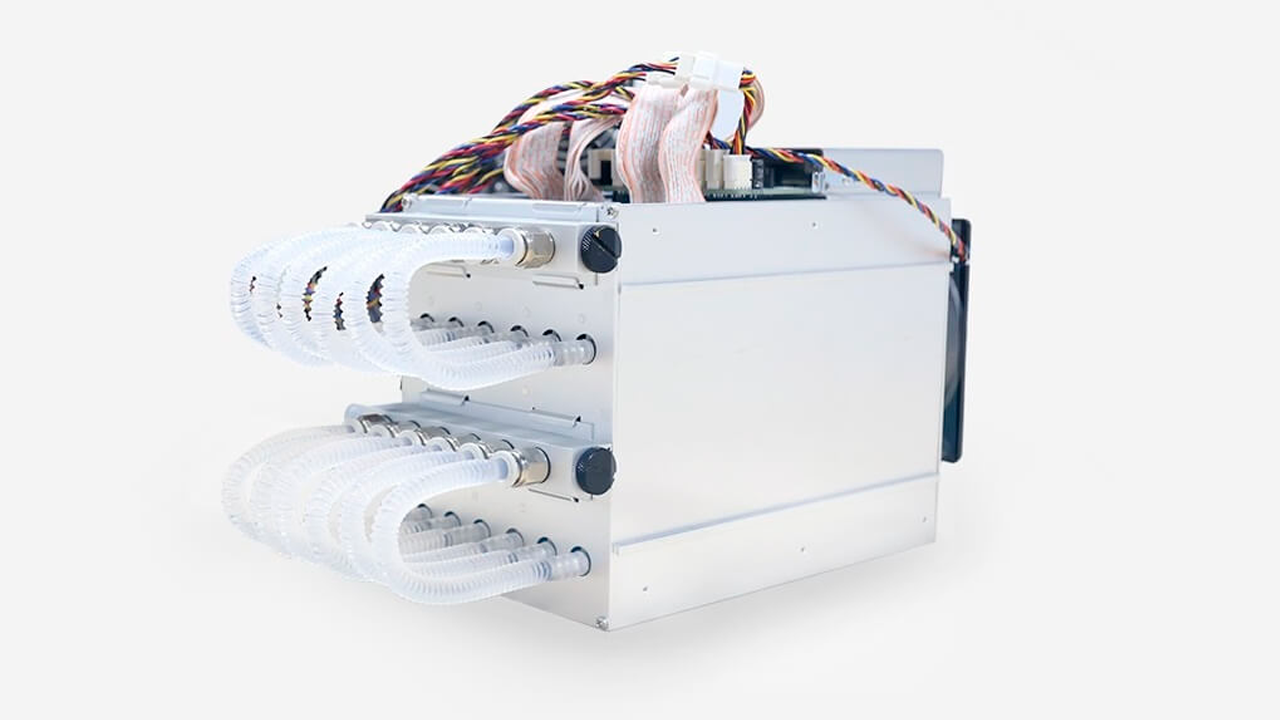

For immersion cooling, the miner is prepared for immersion by dismantling the casing, radiators, and fans. To operate without fans, special spoofers are used. The liquid directly contacts the heated parts, removing heat before being cooled through a chiller or heat exchanger.

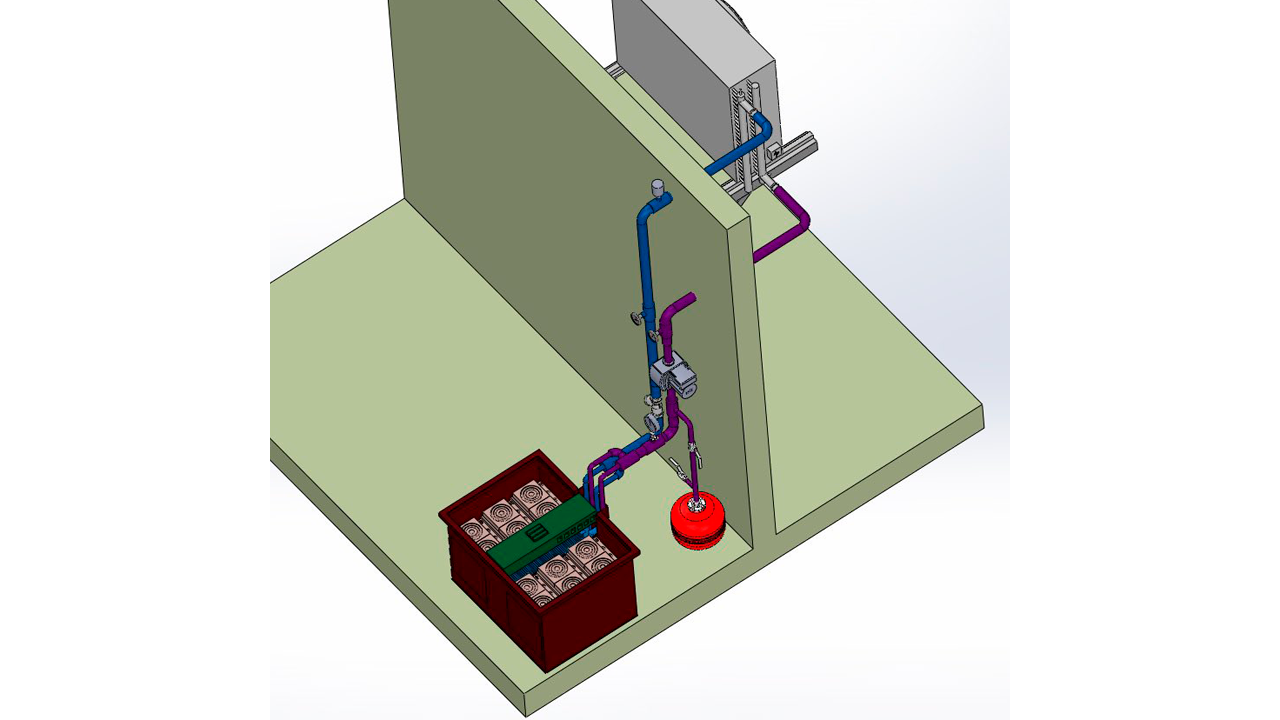

AiPROENERGY offers the HotBox Liu, a unique immersion tank that houses 6 miners with standard axial fans intact, thus eliminating the need for spoofers. Oil actively flows through the machines, cooling the ASIC chips through central heat exchangers. The oil's circulation, driven by the miners' fans, maintains constant ASIC temperature, using secondary cooling options like dry coolers or running water.

Dielectric Liquids

These liquids are categorized into oils (mineral, synthetic, silicone) and fluorocarbons, further divided into two-phase and single-phase based on the cooling cycle. Two-phase liquids evaporate and condense, requiring sealed tanks. Single-phase liquids remain liquid and are circulated through a heat exchanger.

In Detail

For immersion cooling, the miner is prepared for immersion by dismantling the casing, radiators, and fans. To operate without fans, special spoofers are used. The liquid directly contacts the heated parts, removing heat before being cooled through a chiller or heat exchanger.

AiPROENERGY offers the HotBox Liu, a unique immersion tank that houses 6 miners with standard axial fans intact, thus eliminating the need for spoofers. Oil actively flows through the machines, cooling the ASIC chips through central heat exchangers. The oil's circulation, driven by the miners' fans, maintains constant ASIC temperature, using secondary cooling options like dry coolers or running water.

Dielectric Liquids

These liquids are categorized into oils (mineral, synthetic, silicone) and fluorocarbons, further divided into two-phase and single-phase based on the cooling cycle. Two-phase liquids evaporate and condense, requiring sealed tanks. Single-phase liquids remain liquid and are circulated through a heat exchanger.

Advantages of Immersion Cooling

Despite these benefits, most miners globally still rely on air-cooled infrastructure. This persistence prompts an analysis of immersion cooling's listed advantages.

Challenges of Immersion Cooling

Conclusion

Immersion cooling systems are increasingly popular, offering several benefits over traditional cooling methods. However, they are unlikely to completely replace air-cooled systems shortly. The continued development of powerful processors may necessitate the broader adoption of immersion cooling as other systems fail to manage the heat efficiently.

If immersion mining systems interest you, AiPROENERGY is your reliable one-stop shop, offering everything from container delivery and deployment to miner stacking, network architecture setup, on-site services, and workshop repairs in Houston - we've got you covered!

Thank you for your attention.

- Efficient heat removal allows for denser equipment placement and use of high-performance miners without overheating risks.

- Uniform cooling prevents local overheating, extending device lifespan.

- Energy savings by eliminating the need for traditional air-cooling infrastructure.

- Enhanced computing power due to effective cooling.

- Dust and dirt exclusion increases device reliability.

- The use of non-flammable dielectric liquids reduces the need for complex fire systems.

- Operation is noise-free.

Despite these benefits, most miners globally still rely on air-cooled infrastructure. This persistence prompts an analysis of immersion cooling's listed advantages.

Challenges of Immersion Cooling

- Heat Recovery: Efficient heat removal is one part; heat utilization is another challenge, often requiring more expensive and efficient heat exchangers.

- Equipment Warranty: Non-warranty issues may arise since not all miners are designed for immersion.

- Maintenance: Servicing miners can be more cumbersome compared to traditional systems, affecting downtime.

Conclusion

Immersion cooling systems are increasingly popular, offering several benefits over traditional cooling methods. However, they are unlikely to completely replace air-cooled systems shortly. The continued development of powerful processors may necessitate the broader adoption of immersion cooling as other systems fail to manage the heat efficiently.

If immersion mining systems interest you, AiPROENERGY is your reliable one-stop shop, offering everything from container delivery and deployment to miner stacking, network architecture setup, on-site services, and workshop repairs in Houston - we've got you covered!

Thank you for your attention.